In this article, we shall delve into the intricate and highly specialized process involved in the manufacturing of lithium-ion batteries. We will explore each step, from raw materials to the final product, shedding light on the complex engineering and precise techniques employed in this sophisticated industry. Understanding the manufacturing process is crucial to appreciate the remarkable capabilities and widespread applications of lithium-ion batteries.

1.Raw Material Acquisition:

The first stage in manufacturing lithium-ion batteries involves sourcing the necessary raw materials. The key components include lithium carbonate or lithium hydroxide, graphite, metal foils (usually aluminum and copper), electrolyte solution, and various additives. These materials are obtained through mining, chemical synthesis, and refining processes, ensuring high purity and quality standards.

2.Electrode Preparation:

The next step is the preparation of electrodes, which are the heart of the battery. For the positive electrode (cathode), a mixture of lithium metal oxide, conductive additives, and a binder is coated onto an aluminum foil. Similarly, for the negative electrode (anode), a graphite mixture is coated onto a copper foil. These coated foils undergo a drying process to remove solvents, resulting in thin electrode sheets.

3.Separator Assembly:

A crucial component in lithium-ion batteries is the separator, which prevents direct contact between the positive and negative electrodes, ensuring safety and preventing short circuits. Typically, a microporous polymer membrane is used as the separator. It is placed between the electrodes, allowing the movement of lithium ions while blocking electrons.

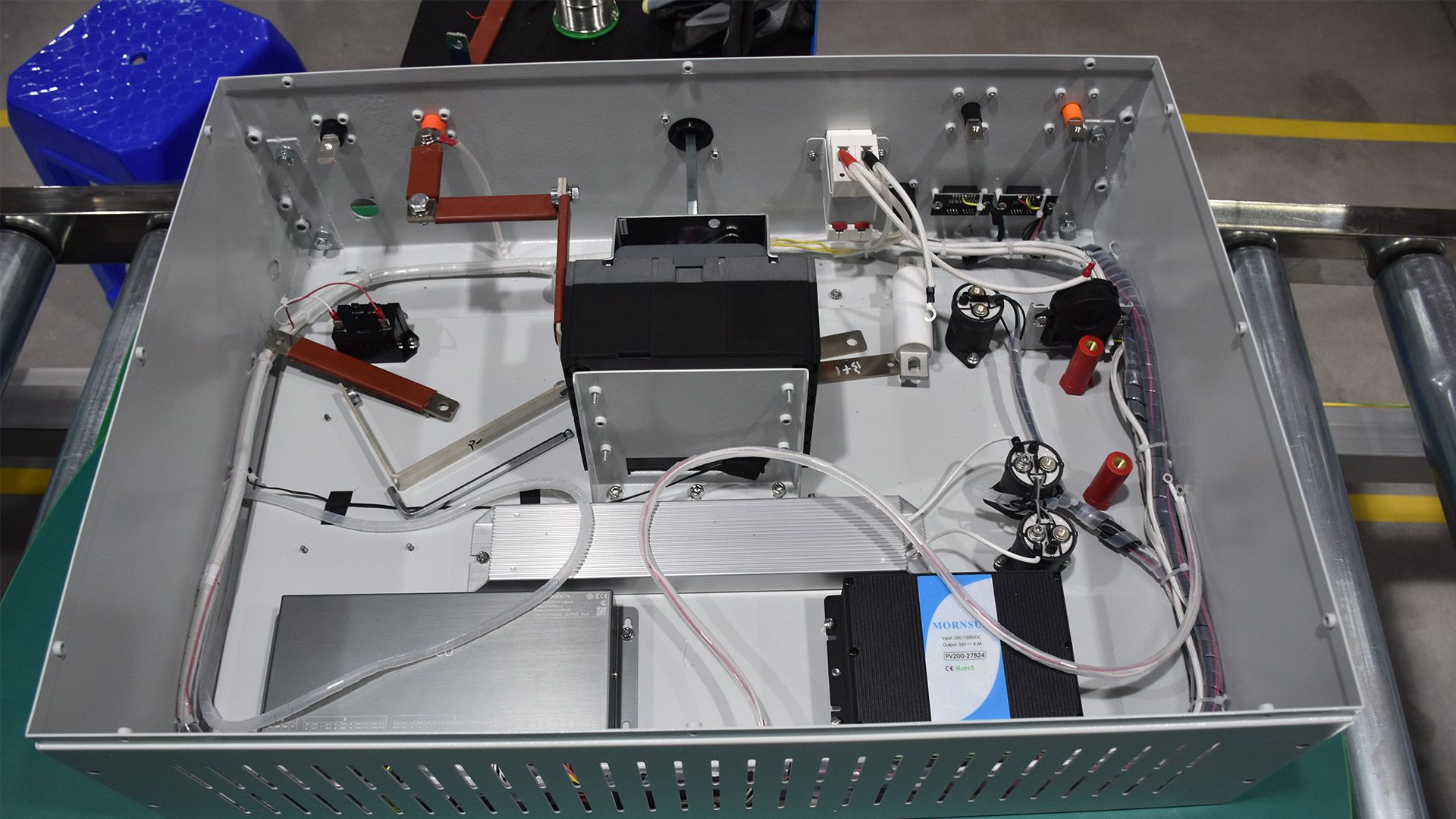

4.Cell Stacking and Enclosure:

In this stage, the prepared electrodes and separator are stacked together, forming a sandwich-like structure. This assembly is then enclosed in a casing, commonly made of aluminum or steel, to protect the delicate internal components. The casing is designed to allow electrical connections and accommodate the electrolyte.

5.Electrolyte Filling:

The next step involves filling the battery casing with the electrolyte solution. The electrolyte is a combination of lithium salts dissolved in an organic solvent. This electrolyte enables the movement of lithium ions between the electrodes during charging and discharging. The filling process requires precision to ensure the correct volume and avoid contamination.

6.Sealing and Formation:

Once the battery casing is filled with the electrolyte, it is sealed tightly to prevent leakage and maintain a controlled environment. The sealed battery then undergoes a formation process, where it is subjected to initial charging and discharging cycles to stabilize its performance and capacity. This process activates the electrochemical reactions within the battery.

7.Quality Control and Testing:

Quality control is a critical aspect of lithium-ion battery manufacturing. Various tests, such as voltage checks, capacity measurements, and safety evaluations, are conducted to ensure that each battery meets the required specifications and safety standards. Batteries that pass these tests move on to the final stage of production.

8.Packaging and Distribution:

In the final stage, the manufactured batteries are packaged, often in protective cases or blister packs, ready for distribution. They are labeled with relevant information, such as voltage, capacity, and safety instructions. The batteries are then shipped to various industries, including consumer electronics, automotive, renewable energy, and medical sectors.

Conclusion:

The manufacturing of lithium-ion batteries is a meticulous and intricate process, involving multiple stages of material preparation, electrode assembly, cell stacking, electrolyte filling, sealing, formation, quality control, and packaging. Each step requires advanced technologies, precise engineering, and stringent quality checks to ensure the production of reliable and high-performance batteries. Understanding this complex manufacturing process helps us appreciate the remarkable capabilities and immense potential of lithium-ion batteries in powering our modern world.